In view of the drawbacks of the traditional weighbridge weighing system, the system is suitable for the intelligent transformation of the electronic weighbridge It can avoid the loss caused by artificial cheating caused by traditional weighing methods, and can improve the work efficiency of personnel and promote the enterprise The application of automation. In the process of vehicle moving, the intelligent weighing subsystem is used to collect the weight of the electronic weighbridge in real time Information, after analysis to select the correct weight information sent to the central control system.

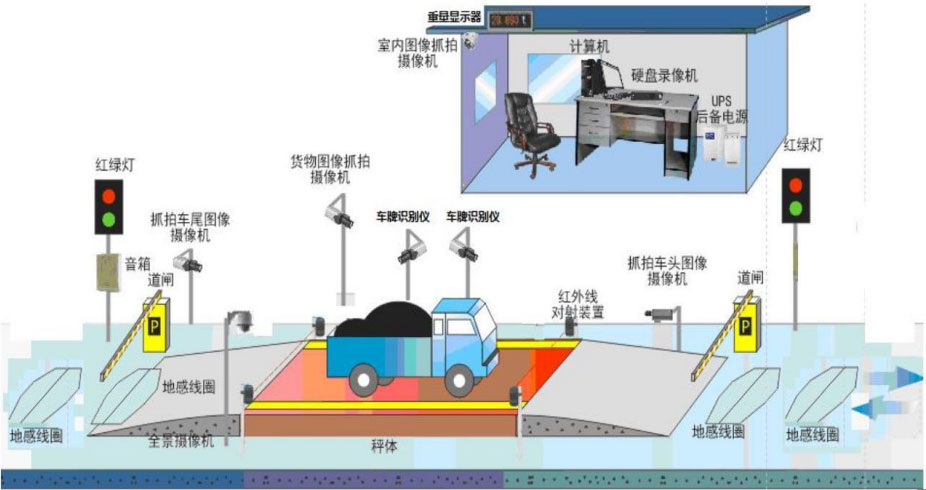

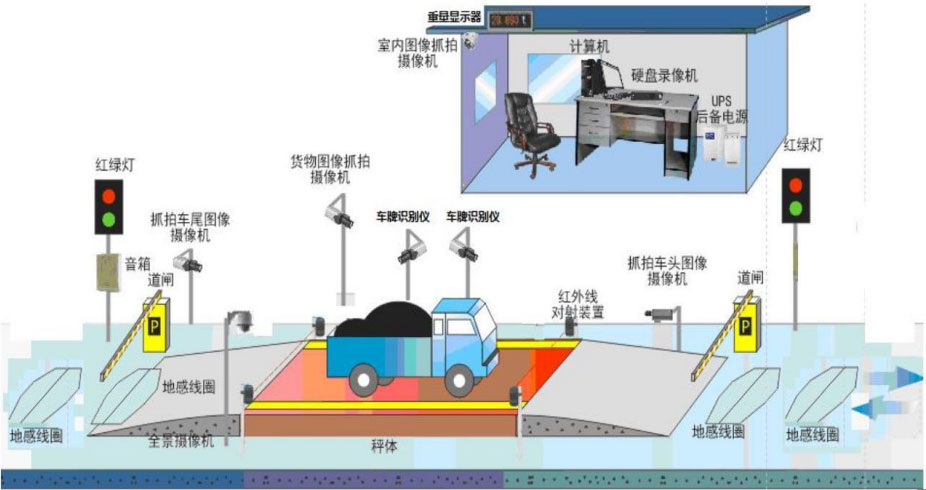

The unattended weighing and loading system is composed of six parts: intelligent weighing and quantitative feeder system, RFID electronic license plate system, video surveillance system, vehicle control system, human-computer interaction system, centralized control system and weighing management software. Among them, the intelligent weighing and weighing system completes the intelligent collection of electronic weighbridge data; RFID electronic license plate system uses Radio FrequencyIdentification technology (radio frequency identification, referred to as RFID) to achieve automatic identification of weighing vehicles; The monitoring system uses surveillance cameras to monitor the vehicle weighing situation 24 hours a day, and videos, screenshots for archiving, in case of later inquiry; Vehicle control system uses ground sensing coil detector and infrared reflector sensor to detect vehicle position, and controls vehicle passage with electronic gear bar, traffic light and other equipment; The human-computer interaction system is equipped with an outdoor all-in-one machine for automatically printing weighing receipts, showing weighing information, and realizing real-time communication between the staff and the driver; The centralized control system is set in the centralized management room, equipped with TV wall, intercom microphone and other equipment to achieve remote weighing management; The weighing management software centrally processes the information collected by the front-end equipment to complete the weighing business. In addition, it can also achieve vehicle management, card management, query statistics and other functions.

The intelligent mineral processing system is mainly used for the separation of ore after crushing, which can carry out ore content and color analysis in the conveying state and carry out content color separation. The separation of non-metal ore in advance can greatly improve the utilization rate of post-stage equipment, increase production and save costs.

The intelligent mineral processing system is composed of chute, feeder, chute, conveyor belt, etc., so that the ore block is single layer, single row, multiple row evenly to the machine irradiation and detection system. Generally, multistage ore feeding is adopted, the first stage controls the feeding amount, the second and third stages line up the ore, and the ore blocks are in a single stable discrete state, and a certain distance is opened between the ore blocks. The detection system uses sensitive elements to determine the absorption, scattering or reflection characteristics of different minerals in optical, magnetic, electrical or radioactive environments as the basis for selection. The main task of the information processing system is to obtain the ore block grade or characteristic quantization data after amplification, noise reduction, shaping, analysis and conversion of the ray activity and optical signal of the ore block from the detection system, and then enter the main control unit after comparing with the predetermined value to make a decision and determine whether to issue a command to the executive mechanism. The actuator mainly has two kinds of mechanical baffle or high pressure air flow. According to the command of the information processing system, the target ore particles can be separated by deviating from the normal movement path.

With the economic development of our country, the coal market is constantly changing and expanding, and the coal transportation is rapidly developing. Trains and automobiles are the two big dragons in coal transportation. In particular, automobile transportation, which has the advantages of flexibility and direct access to customers' homes, has become a million army of coal transportation. To this end, the loading and unloading of the car has become a very important link of the heavy, our company is an old expert in the production of loading equipment, the rapid quantitative car loading system has been produced, is based on the train railway loading system evolved into the loading system, although it has high weighing accuracy, loading speed, high-end advanced technology with intelligent automation, but its system is larger and higher cost. For some small and medium-sized coal mines and small and medium-sized company users, there is still some strength, there is a sense of hope and stop. In order to better adapt to market changes and meet the needs of various users, we have developed diversified vehicle unloading and loading equipment and systems.

It is composed of belt conveyor of upper tower, buffer bin, hydraulic plate gate (1) installed under buffer bin, loading chute installed under plate gate, automobile floor scale, etc. The idea is: The truck box to be loaded is regarded as a weighing bin and the truck floor scale is regarded as a quantitative weighing system. The control system collects the weighing data information of the truck floor scale to control the hydraulic plate gate under the buffer bin. The loading chute is operated to load coal into the car box. Complete the weighing and loading process.

Sales hotline+86 18265477987

Company emailchangrunzhizao@163.com

Company addressJining City, Shandong Province, South Zhang Industrial Park, run intelligent manufacturing South Zhang Industrial Park, run intelligent manufacturing