GDH activated disc vibratory feeder is a kind of disc feeder in the material conveying and mixing system.

Main technical features:

1, smooth operation, fast speed, low noise, good explosion-proof performance, environmental protection products.

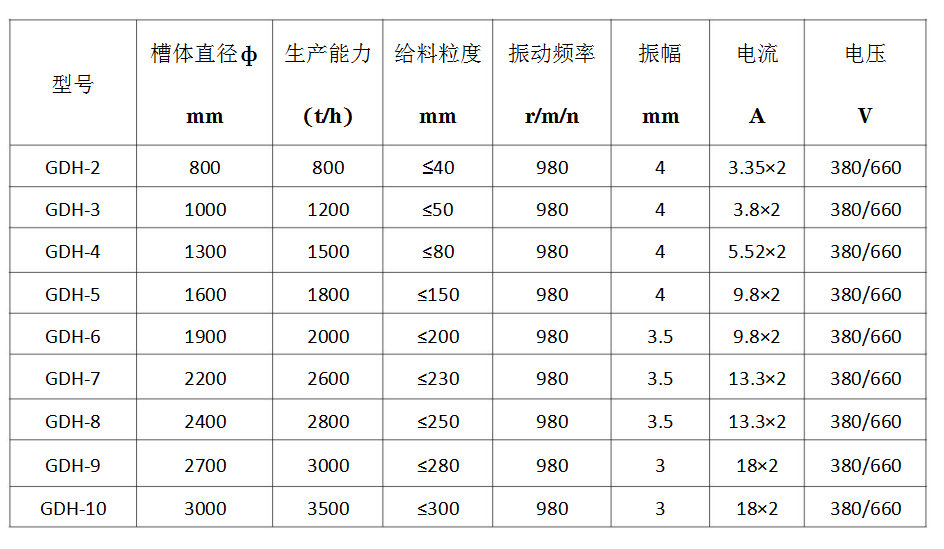

2, high efficiency and energy saving, low cost, large feeding capacity, up to thousands of tons per hour, ordinary models unparalleled.

3, according to user needs, the feeding amount can be adjusted at will, automatic and manual. If used with frequency converter, can

Achieve remote control.

4. Equipped with arch breaking device, it can better overcome the phenomenon of gas blockage and arch formation in the warehouse to ensure that the material is unimpeded.

5, simple installation, small use space, convenient replacement model, low cost of technical transformation, short cycle, quick effect.

6, reliable quality, stable performance, general parts accounted for more than 90%, easy installation and maintenance.

7, auxiliary equipment is complete, the use of complete functions, the use of a wide range of performance.

8. Multiple sets of buffer rollers are set at the bottom of the bin body, which enhances the impact resistance and protects the (nail belt) ring strength

Force tape, improve the service life of the (nail belt) ring strong tape.

Through the funnel and gate, the material falls on the special flame-retardant conveyor belt with wear-resistant, tear resistant, impact resistant and flame retardant. The huge warehouse pressure is alleviated by the funnel, and the self-weight of the downstream material and a small amount of warehouse pressure are borne by the ram and the closely packed rollers below. By driving the roller, the driving device makes the uniform speed line of the conveyor belt move to achieve continuous and uniform feeding. If the material stuck on the belt cannot be unloaded automatically due to the large water content, the belt cleaner under the reversing drum will forcibly unload the material. After the motor changes the output speed through the reducer, the driving device is driven by the reducer to rotate the transmission drum to work. The driving device, transmission drum, reversing drum, roller and cleaner are all fixed on the bottom frame. The bottom frame is mounted on the side panel of the box by bolted connection. During the overhaul, the gate can be closed to seal the material in the silo, and the following maintenance can be convenient.

Sales hotline+86 18265477987

Company emailchangrunzhizao@163.com

Company addressJining City, Shandong Province, South Zhang Industrial Park, run intelligent manufacturing South Zhang Industrial Park, run intelligent manufacturing