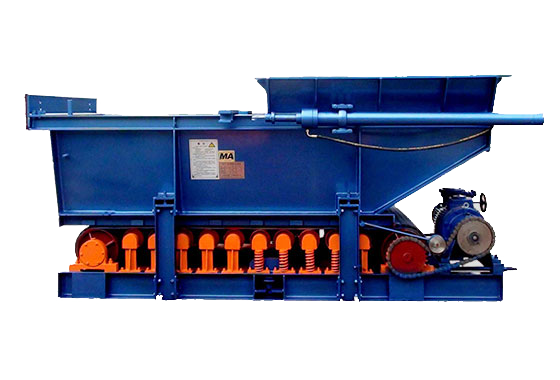

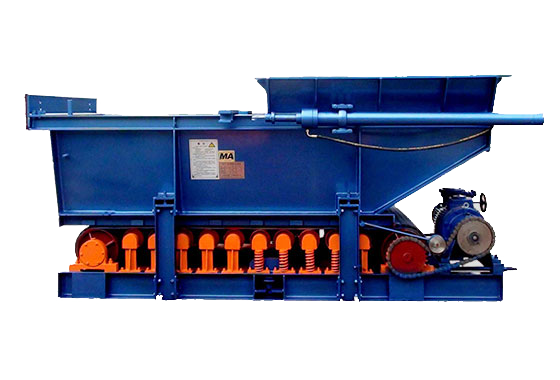

The chain-type feeder includes an electronic control system, which includes an on-site control system and/or a remote control system. The ring chain of the plate feeder is equipped with a number of scrapers, and after a number of scrapers, the reciprocating rotation movement is better to ensure the cleaning of the site and the effective recovery of coal, and the production efficiency is high.

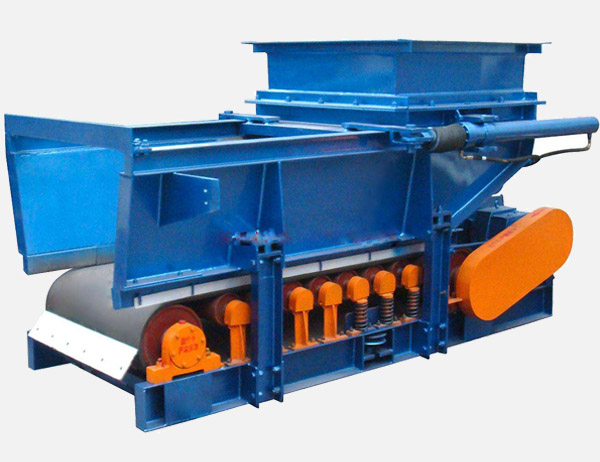

The connecting section is installed in the lower part of the bin mouth, under which a guide groove is installed, and a chain plate feeding device is installed under the guide groove. The chain plate feeding device comprises a driving drum, a reversing drum, a conveying chain and a chain plate. The bottom frame comprises a support plate. The driving device and chain plate feeding device are installed on the bottom frame and can be adjusted. In the upper part of the feed guide groove, a maintenance gate mechanism is installed to realize the opening and closing of the feed port during maintenance.

The material in the bin enters the guide trough through the connecting section and falls on the support plate. When the feed device of the chain plate is stationary, the material finally stops moving by the internal friction force and forms a static accumulation at a certain Angle at the discharge port. When the driving drum begins to rotate under the driving device, it drives the movement of the conveying chain and the chain plate, drives the material on the plate and between the chain plate to the discharge port, and the material is continuously discharged from the discharge port, thus completing the feeding process. To change the feed amount, the feed amount can be adjusted by changing the opening of the gate, the output shaft speed can be changed by adjusting the speed control handwheel of the reducer, the running speed of the chain plate can be changed, and the motor speed can be changed by adjusting the frequency of the inverter.

The driving device can be driven by hydraulic drive or electric drive or pneumatic drive according to user needs. The hydraulic drive device uses hydraulic motor to drive the drum to transport materials, achieve soft start and realize heavy load start feeding.

The gate track is arranged on the upper part of the guide trough, the gate track is arranged on the gate track, and the hydraulic cylinder of the gate is arranged on one side or both sides or in the middle of the gate, and the hydraulic cylinder of the gate pushes the gate to run reciprocally along the gate track to close or open the inlet of the connecting section. The hydraulic station of the gate hydraulic cylinder and the hydraulic station of the driving device are the same hydraulic station, and the power of the driving hydraulic station is used to drive the gate. The powerful power makes the gate open and close with great strength and speed.

The chain-type feeder includes an electronic control system, which includes an on-site control system and/or a remote control system. Remote control system includes fully distributed control structure, semi-distributed control structure or point distributed control structure, fully distributed control structure includes integrated PLC centralized control system, local control station and power control system, integrated PLC centralized control system and local control station between the open Contorlnet bus structure, The integrated PLC centralized control system is connected to the local control station through Contorlnet(control network) bus network, and the local control station is responsible for the control of field equipment, flow calculation and data collection.

| 型号 | 功率/KW | 电压/V | 调速方式 | 最大带速/(m/s) | 额定给料量/(t/h) | 重量/kg |

| GLLB800/11/S | 11 | AC380 AC660 AC1140 可选 | 手动 | 0.6 | 800 | 4100 |

| GLLB800/11/B | 变频 | 4200 | ||||

| GLLB2000/11/S | 11/15① | 手动 | 0.75 | 2000 | 5500 | |

| GLLB2000/11/B | 变频 | 5600 | ||||

| GLLB3300/15/S | 18.5 | 手动 | 3300 | 3300 | 6500 | |

| GLLB3300/15/B | 变频 | 6600 | ||||

| GLLB4400/22/S | 22 | 手动 | 0.75 | 4400 | 7600 | |

| GLLB4400/22/B | 变频 | 7700 |

Sales hotline+86 18265477987

Company emailchangrunzhizao@163.com

Company addressJining City, Shandong Province, South Zhang Industrial Park, run intelligent manufacturing South Zhang Industrial Park, run intelligent manufacturing