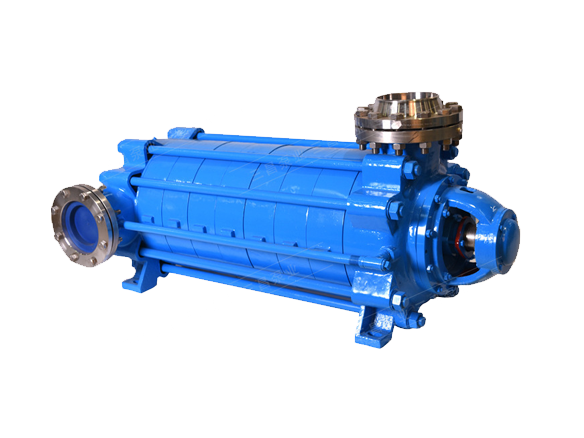

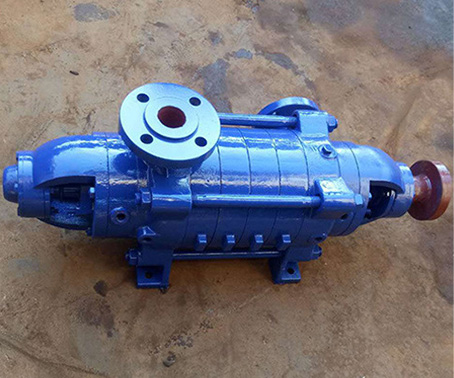

The rotor part of MD type mine multistage centrifugal pump is mainly composed of shaft and impeller, shaft sleeve, balance plate and other parts installed on the shaft, the number of impeller is determined according to the pump series. The parts on the shaft are fastened by flat keys and shaft nuts so that they are integrated with the shaft. The whole rotor is supported by both ends of the rolling bearings or plain bearings, bearings depending on the model, are not subjected to axial force, its axial force is balanced by the balance plate. The pump allows the rotor to travel axially in the pump housing during operation, and the centripetal ball bearing cannot be used. Rolling bearings are lubricated with grease, sliding bearings are lubricated with thin oil, and oil rings are self-lubricated and cooled by circulating water. The sealing surface between the inlet section, the middle section and the outlet section of the pump are sealed with molybdenum disulfide grease, and the sealing ring and guide vane sleeve are installed between the rotor part and the fixed part. When the wear degree of the sealing ring and guide vane sleeve has affected the working performance of the pump, it should be replaced.

The sealing form of multistage centrifugal pump for mining has two kinds: mechanical seal and packing seal. When the pump uses the packing seal, the position of the packing ring should be placed correctly, the tightness of the packing must be appropriate, and the liquid can leak out drop by drop. Various sealing components of the pump are installed in the sealing chamber, and a certain pressure of water should be passed into the chamber, and the water seal, water cooling or water lubrication should be allowed. A replaceable sleeve is installed at the shaft seal to protect the pump shaft.

It is suitable for use with water pump in the environment of explosive gas such as methane or coal dust, the mining face and roadway under the mine with explosion risk.

1, under the condition of clean water (containing solid particles less than 0.1%), the operation of 5000h without major repair, the efficiency decline does not exceed 6%;

2, containing solid particles less than 0.1% ~ 1% of the sewage conditions, 3000h without overhaul, efficiency decline does not exceed 5%;

3, containing solid particles 1 ~.5% sewage conditions, 2000h operation without overhaul, efficiency decline does not exceed 6%.

MD horizontal wear-resistant multistage centrifugal pump | |||

序 | MA | KA | 型号规格 |

1 | MBB140123 | KBB140037 | MD6-25×(2~12) |

2 | MBB140120 | KBB140047 | MD6-50×(2~12) |

3 | MBB140124 | KBB140048 | MD6-80×(3~12) |

4 | MBB140164 | KBB140071 | MD12-25×(2~12) |

5 | MBB140125 | KBB140057 | MD12-50×(2~12) |

6 | MBB140179 | KBB140058 | MD12-80×(3~12) |

7 | MBB140184 | KBB140066 | MD25-30×(2~10) |

8 | MBB140182 | KBB140067 | MD25-50×(2~12) |

9 | MBB140172 | KBB140068 | MD25-80×(3~12) |

10 | MBB140154 | KBB140040 | MD46-30×(2~10) |

11 | MBB140172 | KBB140041 | MD46-50×(2~12) |

12 | MBB140136 | KBB140042 | MD46-80×(3~12) |

13 | MBB140161 | KBB140050 | MD85-45×(2~10) |

14 | MBB140155 | KBB140046 | MD85-67×(2~10) |

15 | MBB140128 | KBB140052 | MD85-80×(3~12) |

16 | MBB140138 | KBB140055 | MD100-25×(2~10) |

17 | MBB140159 | KBB140051 | MD120-50×(2~12) |

18 | MBB140151 | KBB140061 | MD150-50×(2~12) |

19 | MBB140131 | KBB140062 | MD150-80×(3~12) |

20 | MBB140174 | KBB140059 | MD150-100×(3~12) |

21 | MBB140173 | KBB140060 | MD155-30×(2~10) |

22 | MBB140118 | KBB140063 | MD155-67×(2~10) |

23 | MBB140152 | KBB140065 | MD200-50×(2~12) |

24 | MBB140135 | KBB140072 | MD200-100×(3~10) |

25 | MBB140142 | KBB140069 | MD280-43×(2~10) |

26 | MBB140127 | KBB140070 | MD280-65×(2~10) |

27 | MBB140122 | KBB140064 | MD280-95×(4~10) |

28 | MBB140178 | KBB140056 | MD360-40×(2~10) |

29 | MBB140180 | KBB140054 | MD360-60×(4~10) |

30 | MBB140146 | KBB140044 | MD360-95×(4~10) |

31 | MBB140168 | KBB140038 | MD450-60×(2~10) |

32 | MBB140167 | KBB140039 | MD450-95×(4~10) |

33 | MBB140169 | KBB140043 | MD500-57×(2~10) |

34 | MBB140145 | KBB140045 | MD600-60×(2~10) |

35 | MBB140137 | KBB140049 | MD720-60×(2~10) |

36 | MBB140132 | KBB140009 | 200MD43×(2~10) |

Sales hotline+86 18265477987

Company emailchangrunzhizao@163.com

Company addressJining City, Shandong Province, South Zhang Industrial Park, run intelligent manufacturing South Zhang Industrial Park, run intelligent manufacturing